Modernize With Industrial IoT

Reduce downtime, improve safety, and optimize costs.

OT Data, Business Results

We connect OT and IT reliably, improving uptime without disrupting scheduled production windows.

Protocol bridges, edge analytics, and predictive maintenance unlock measurable OEE and throughput.

For Industrial Leaders

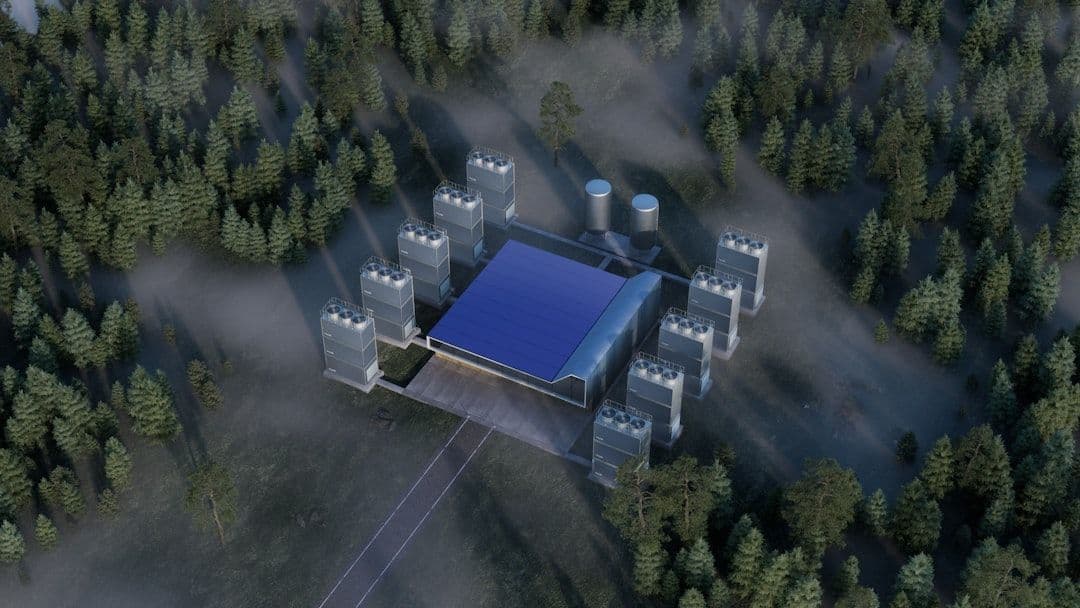

Systems designed for manufacturers, energy, and logistics.

Monitor production lines in real time.

Optimize grids and plants.

Track fleets and warehouses.

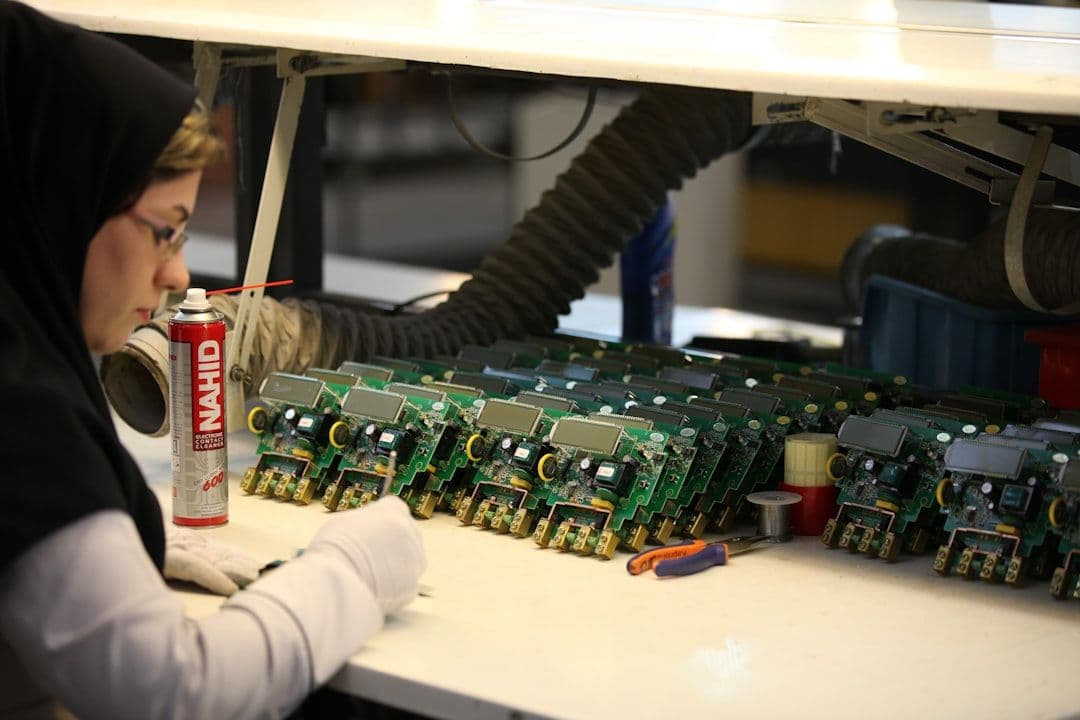

Add connectivity to products.

Industrial IoT Services

Solutions that optimize operations and reduce downtime.

Minimize downtime.

Track KPIs on the factory floor.

Retrofit legacy machines.

Centralize oversight.

Process data near source.

Our IIoT Delivery Process

We align industrial expertise with agile methods for reliability and ROI.

Define use cases and ROI.

Secure, fault-tolerant systems.

Validate in small deployments, scale up.

Ensure reliability and adoption.

AI That Drives Industry 4.0

AI drives efficiency, safety, and uptime in industrial operations.

Machine Telemetry

Vibrations, temperature, wear.

Production Metrics

Yield and throughput.

Energy Data

Usage and costs.

Maintenance Logs

Historical servicing.

Environmental Data

Facility and climate conditions.

Predictive Models

Anomaly Detection

Risk Scoring

Forecasting

Optimization

Predictive Maintenance Alerts

Catch failures early.

Efficiency Dashboards

Track OEE and KPIs.

Energy Optimization Reports

Cut waste and costs.

Safety Alerts

Spot dangerous conditions.

Process Automation Tools

Streamline operations.

Reduce downtime, improve safety, and optimize costs.

Article•

Explore how Digital Twins are transforming smart transportation through predictive maintenance, AI integration, and vendor-neutral system design; powered by semantic modeling and knowledge graphs.

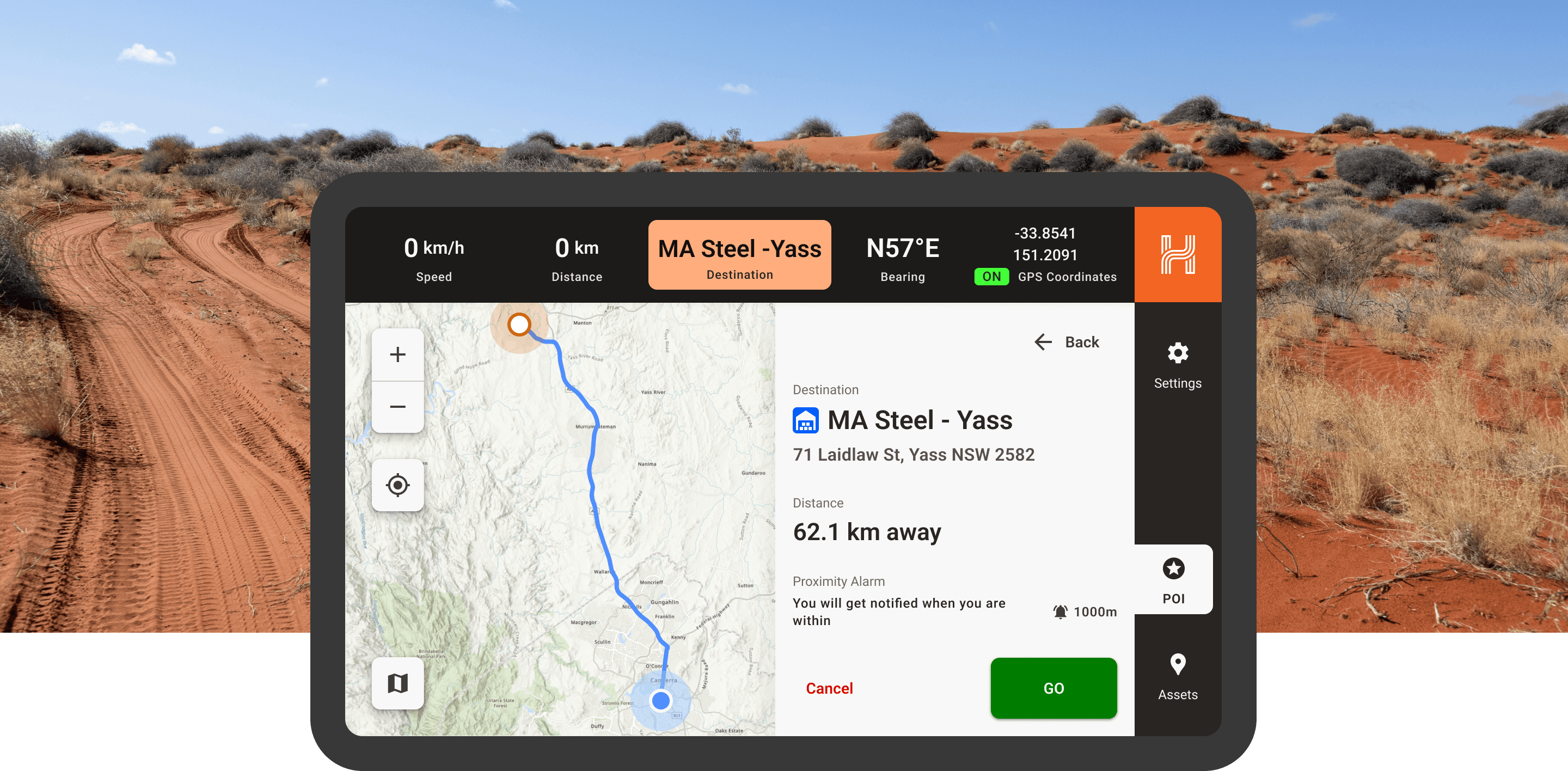

Case Study•

Built with Hema Maps, this rugged Android app powers navigation and asset tracking across remote Australia—even offline. Designed by White Widget.