Digital Twins in IoT-enabled Transportation: From Predictive Maintenance to AI Integration

Last Updated on September 16, 2025

by White Widget Team

Planet Volumes | Unsplash

Need help with Digital Twins?

Challenges of IoT in transportation

The transportation industry is in the middle of a rapid digital transformation. Everything from autonomous vehicles to public transport fleet management hinges on robust software that can handle massive amounts of data from an ever-widening array of sources. Sensors, batteries, OBD-II, and kiosks, to mention a few examples.

Organizations find themselves constantly wrestling with the challenges of working with this much complexity. Addressing these challenges is exactly the promise of the Internet of Things (IoT). IoT aims to help organizations run smarter, access better data, and make faster decisions by connecting systems, machines, and infrastructure.

Leveraging these advantages is critical for the transportation industry. It’s no surprise that IoT is at the center of its digital transformation and a key part of Industry 4.0.

However, with all the power IoT promises, it can only deliver as much as it can solve one of its biggest concerns: interoperability.

Why interoperability is important in IoT

McKinsey has consistently identified interoperability as one of the most critical challenges limiting the full value of IoT solutions. Interoperability in the Internet of Things, or inter-IoT, means the ability to seamlessly work with a diverse set of devices and systems from different manufacturers.

A lack of inter-IoT is a major driver of vendor lock-in. In the transportation sector, an example issue is difficulty integrating IoT for EV cars from different suppliers. Without a common data standard, the broader IoT ecosystem struggles to "speak the same language." This increases integration costs and makes it difficult to adopt more flexible or innovative solutions over time.

Beyond long-term flexibility, limited inter-IoT reduces return on investment (ROI) and constrains decision-making. A sensor's data alone is not useful. The true power of IoT comes from combining and analyzing data from different parts. This helps create smarter operations.

As early as 2015, McKinsey highlighted this issue with IoT sensors in their report:

"Less than 1 percent of the data being generated by the 30,000 sensors on an offshore oil rig is currently used to make decisions. And of the data that are actually used—for example, in manufacturing automation systems on factory floors—most are used only for real-time control or anomaly detection. A great deal of additional value remains to be captured, by using more data, as well as deploying more sophisticated IoT applications, such as using performance data for predictive maintenance or to analyze workflows to optimize operating efficiency."

Source: McKinsey Global Institute, The Internet of Things: Mapping the Value Beyond the Hype, 2015.

Strong Inter-IoT allows us to connect more of our IoT data to extract more powerful and accurate insights.

IoT and Digital Twins

Aside from needing inter-IoT, organizations must also test their IoT infrastructure even before deploying smart device hardware components in costly real-world environments. Gathering data is important for investments of this scale.

That’s why we need solutions that can mirror physical systems safely and efficiently. Imagine being able to test thousands of IoT interactions without laying a single wire or shutting down an entire parking wing. That’s the promise of Digital Twins.

Digital Twins are emerging as a key tool to implement inter-IoT at scale.

What is a Digital Twin?

A Digital Twin is a virtual representation of a physical object or system that:

- Reflects the real-time state of its counterpart

- Captures changes in state (e.g., sensor values)

- Enables prediction, simulation, and monitoring.

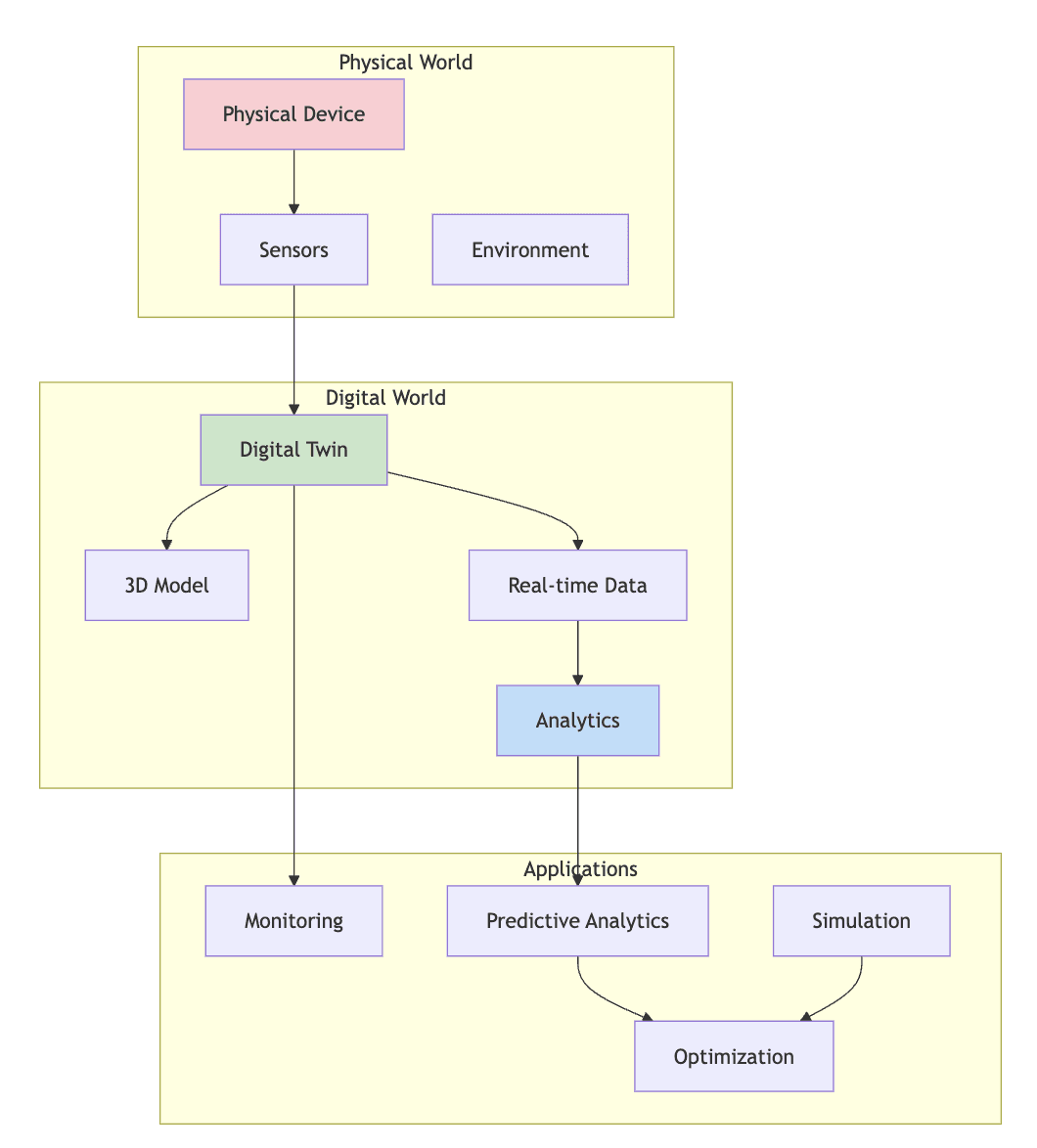

Fig. 1: The diagram illustrates the relationship between the physical world and the digital world in a Digital Twin system.

In Figure 1, we show the relationship between the physical and digital world in a Digital Twin System. The physical device, along with its sensors and environment, continues to stream data to its digital counterpart. The digital twin can integrate a 3D model or real-time data coming from the sensors, and process it through the analytics engines. These insights power key applications such as monitoring, predictive analytics, and simulation, which in turn support ongoing optimization of the physical system.

Digital Twins aggregate a wide range of data from the IoT platform into a virtual model of the real asset. This shifts the focus from monitoring scattered sensor readings to understanding and managing the actual physical system they represent.

Digital Twins help you:

- Identify optimizations, reduce costs, and support informed decisions.

- Analyze trends and compare current vs. normal behavior.

- Simulate the behavior of the devices before physical deployment

- Reduce the hardware and operational costs by validating the logic in silico

- Detect anomalies and spot early warning signs.

- Monitor and manage devices from different manufacturers.

Benefits of Digital Twins in transportation

Digital Twins are already accelerating industry leaders today.

Mercedes Benz built its “Digital First” transformation by integrating AI with Digital Twin technology using Nvidia’s Digital Twin technology “Omniverse”.

Digital Twins help them plan, adjust, and check assembly areas for safe distances, wide aisles, and fire protection. Virtual testing speeds up production, improves transparency, and makes processes more flexible without the need for expensive hardware.

According to Mercedes Benz, Digital Twins halved the time to construct or convert an assembly hall while also improving processes.

Mercedes Benz is now able to interact directly with its suppliers, reducing their coordination processes by 50%.

Alstom used Digital Twins during the development of their automatic train operation. Digital Twins helped them speed up their work by allowing engineers to review issues found in the field. It also enabled engineers to test new software before installing it on the train.

The developed automatic train operation improved their freight-only lines’ efficiency in negotiating braking curves. This led to maintenance savings because of less brake wear and tear and improved energy savings.

Digital Twins and AI

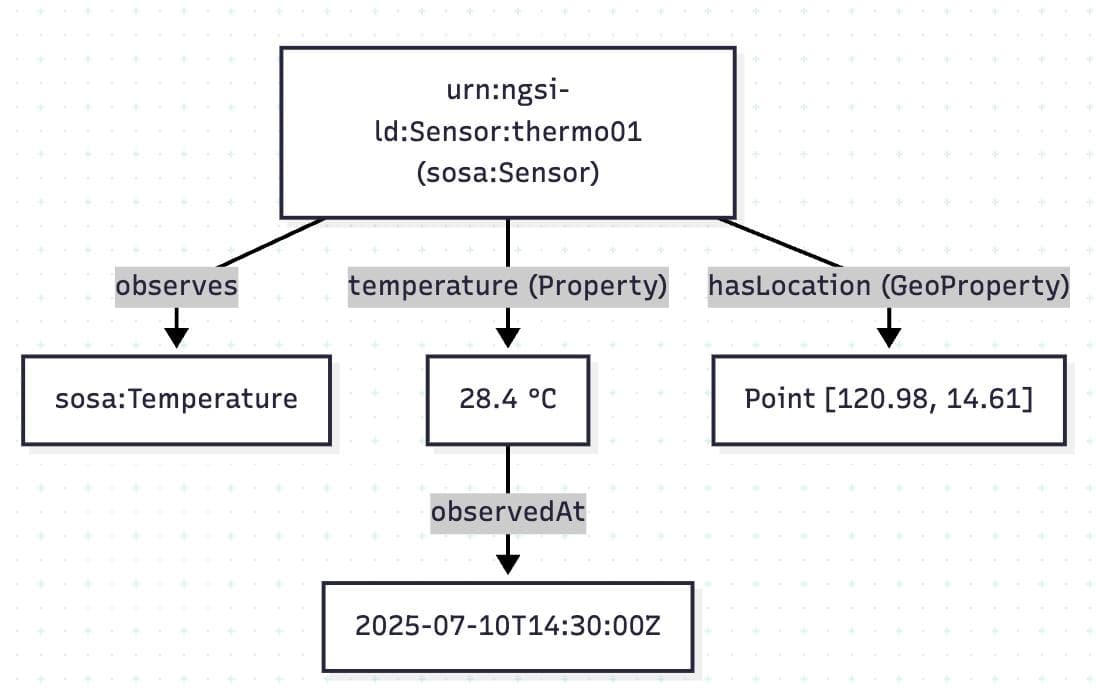

Some Digital Twin platforms (like Azure Digital Twins) are architected with Ontology/Semantic modeling support that provides better context and integration with AI systems. Ensuring that the data follows a semantic model allows portability of the data without losing any context. The illustration below in Fig. 2 describes the difference between raw telemetry logs and the structured semantically rich data that can come from a Digital Twin system. Structuring data this way allows us to connect them into contextually meaningful ensembles, such as with a Knowledge Graph.

New to Knowledge Graphs?

We’ve written a quick explainer to help you understand how Knowledge Graphs work and why they’re essential for scaling intelligent systems.

Fig. 2B Structured telemetry data

{

"sensor_id": "thermo01",

"value": 28.4,

"timestamp": "2025-07-10T14:30:00Z"

}

Fig. 2A Raw telemetry logs

Augmenting the Digital Twin system with Graph Technologies means having the power to query devices state and ask questions like:

- Among the vehicles, which ones are electric, currently parked in covered lots, and have a temperature below 30° C?

- Which of those vehicles needs servicing already based on the battery health?

To achieve this, Microsoft Azure uses its own graph technology in its product Microsoft Data Twins and a data modeling standard to run queries across the device fleet, making the approach easier than browsing through the raw telemetry logs that lack structure, and require processing before having to be able to extract insights from the fleet.

Having a Digital Twin therefore allows visualization and complex querying of fleet real-time unlike in raw telemetry logs that require preprocessing steps.

For teams working with Microsoft Azure Digital Twins, they use a modelling standard called Digital Twin Definition Language (DTDL). This enables users to run graph-based queries.

For teams working with open-source Digital Twin platforms, telemetry data can be modeled more flexibly, either using custom formats or established semantic standards like NGSI-LD. This standard, used in platforms like Fiware, can be integrated into a Knowledge Graph to power large-scale reasoning and analytics.

Learn how we use Graphwise GraphDB and NGSI-LD to unlock intelligent insights at scale:

How to mitigate vendor lock in

No standard data model exists across all IoT devices, and communication protocols may vary between different manufacturers.

Consider how different the process of retrieving battery temperature is between these battery protocols:

Table

Comparison of two EV battery protocols

| Feature | SBS (SMBus) | CAN Bus (BMS) |

|---|---|---|

| Data Format | 16-bit unsigned integer | 8-byte frames; each byte can represent a sensor value |

| Unit | 0.1 Kelvin | 0.1°C |

| Method | Request/Response | Broadcast Model |

| Example | 1. Send the Temperature() command (0x08) | 1. Monitor messages with CAN ID 0x356 |

| 2. Read little-endian response: 0xD0 (low byte) and 0x07 (high byte) | 2. Translate [0x1E, 0x00, 0xF4, 0xFF, 0x2C, 0x00, 0x00, 0x00] as Voltage = 0x001E → 3.0 V, Current = 0xFFF4 → -1.2 A, Temperature = 0x2C → 4.4 °C | |

| 3. Combine the bytes 0x07D0 and convert from 0.1 Kelvin (201.8 K) |

Sources: Smart Battery (SMBus) Data Specification, CAN Bus (BMS) Protocol for Battery Communications

If a fleet management system only supports CAN (BMS), certain assumptions can be made over time:

- The system may exclude the ability to transmit device commands, relying solely on passive data reception.

- Downstream applications may assume temperature values are always 0.1°C per unit.

These can make switching vendors later costly and complex because of the need to evaluate and undo the impact of these assumptions across the entire system.

A well-architected Digital Twin system can reduce hardware vendor lock-in. It does this by separating the data model and logic from devices and platforms. This means physical devices can be changed without affecting the logic in the inter-IoT system.

By decoupling the device data model, hardware can be rolled out in manageable batches rather than all at once. This phased approach reduces risk and enables data-driven adjustments as needed.

Digital Twins have the capability to simulate new devices, demonstrating their functionality within the entire system prior to their real-world implementation.

Getting started with Digital Twins

Several platforms can be used to create Digital Twin systems for IoT development. Some specialize in creating digital versions of physical systems using 3D visualization. Others focus on semantic modeling and support for more complex, logic-based systems.

Here is a quick look at the top providers and their key differences:

Table

Comparison of Digital Twin Platforms for Transportation

| Platform | 3D Visualization | Semantic Modeling | AI Integration | Transportation Use Case | Why It Matters for Business |

|---|---|---|---|---|---|

| NVIDIA Omniverse | Built-in real-time 3D engine | Structural only (no domain logic) | Direct support within platform | Manufacturing for autonomous vehicles | Optimized for 3D factory simulation, layout design, and real-time process testing |

| AWS IoT TwinMaker | External tools via connectors | No semantic modeling features | Connects to AWS AI/ML services | Predictive Maintenance for Rail Systems | Enterprise-grade support and AWS ecosystem. AWS' consistent cost structure is suitable for applications requiring infrequent device updates. |

| Fiware | Requires third-party tools | NGSI-LD, RDF | Requires external AI integration | Smart city traffic optimization | Open-source and vendor-neutral. Strong semantic support and AI integration. |

| Azure Digital Twins | Integrates with Azure and third-party 3D tools | DTDL | Integrated with Azure AI services | Optimizing EV charger deployment | Enterprise-grade support with mature semantic modeling. Strong integration across Azure ecosystem. |

Sources: NVIDIA Omniverse, AWS IoT TwinMaker & Comparison between Digital Twin platforms, Fiware, Azure Digital Twins

When Not to Use Digital Twins

Digital Twins can be incredibly useful, but they’re not the answer to every problem. In some cases, the complexity, cost, or scope of a Digital Twin just doesn’t make sense. Here are a few situations where it might not be the right tool for the job:

- Isolated IoT devices or simple systems

If your project involves simple, stand-alone IoT devices that don’t really talk to each other or interconnect in a larger system, using Digital Twins may be over-engineering. In these cases, using a traditional database or basic monitoring tools is usually more practical and cost-effective.

- Ideally, a Digital Twin system should be able to simulate complex relationships and behavioral logic. If you’re just visualizing raw telemetry, a basic dashboard is much more cost-effective.

- Short-term projects Digital Twins offer cumulative value over time by predicting and simulating potential issues from long-term data. Simple, short-term projects may get limited ROI from Digital Twins.

- Low-latency requirement

There can be some latency between the physical device and its Digital Twin due to

- The layers of abstraction involved in a Digital Twin system

- The communication protocol used

- The cloud infrastructure

While there are strategies to mitigate this such as edge computing or emerging communication protocols, it’s worth weighing the tradeoffs to determine whether Digital Twins are the ideal solution in this scenario.

As a rule of thumb, you can consider using a Digital Twin system when you need to mirror, reason about, or simulate the behavior of a real-world system, especially when it involves complex relationships, dynamic states, or predictive control. It’s also a useful abstraction that helps us innovate our smart transportation systems without inflicting high costs later.

Turning Transportation Data Into Smarter Systems

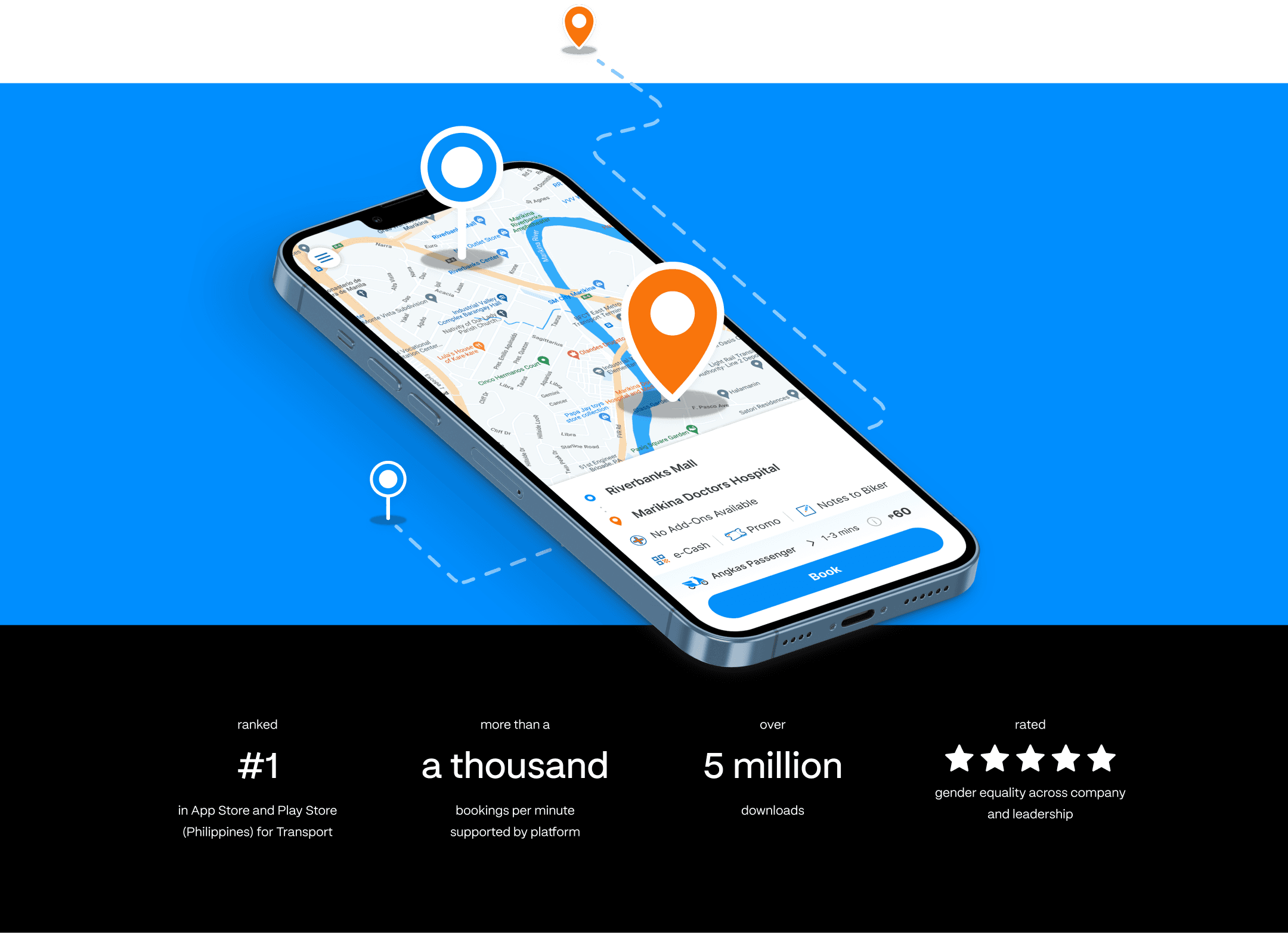

At White Widget, we bring deep experience in transportation systems, having worked with platforms like Angkas and Grab to solve real-world challenges at scale.

We understand the unique demands of your industry, from optimizing rider and driver operations to developing IoT systems that can scale seamlessly across cities and platforms.

About the Authors

White Widget Team is known for delivering holistic, award-winning software solutions across diverse sectors such as transport, healthcare, and media, emphasizing a comprehensive approach to digital innovation, since the company was founded in 2012.

Primary Author

Justine O. , a software engineer with broad domain experience, specializes in building connected systems and integrating hardware devices into larger digital infrastructures.

Contributors

Jermaine P. a data engineer who focuses on emerging developments in AI and machine learning. A researcher and university educator, he's co-authored multiple papers on the subject, with special attention to NLP, semantic networks, and enhancing AI models using various techniques.

Article•

The Road to Trustworthy LLMs: How to Leverage Retrieval-Augmented Generation

People say generative AI is prone to hallucinations, but using specific techniques we can greatly enhance both precision and transparency. Join us as we take you on a survey of how Retrieval Augmented Generation, a.k.a. RAG, can show you what's behind the AI curtain.

Case Study•

State-of-the-art ride hailing platform — relied on by millions

Angkas is the most popular motorcycle taxi platform in the Philippines. We built and designed a massive ride hailing platform, consisting of 7 digital properties on 3 platforms (Web, Android, iOS) in a record 7 months, across 4 cities.